Classification:

Tiercel-RTR-ZD-13130

Fully automatic dual-lR tape feeding and ejection inspection machine

Application: Applied to shipment inspection of finished products after taping, it can inspect supplier shipments to screen defects and ensure buyers receive qualified products.

• Customized Spectral Light Source

• High-speed Camera Inspection

• Supports Rapid Product Changeover

Capability

|

Project |

Content |

|

Product types |

suitable for WLP, SOT, SOP, QFN, and other packaged ICs |

|

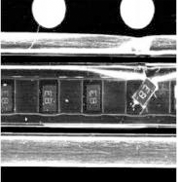

Inspection Items |

Tape sealing, character inspection, plastic-sealed body, pins, hidden cracks, etc |

|

Tray and transmission method |

Automatic loading and unloading |

|

Lens and resolution |

0.3X 2448*2048 |

|

Tape Width |

Automatic track width adjustment, ranging from 8-24mm (Customizable/Quick-changeable) |

|

Reel Disk Size |

7" / 13" |

|

UPH |

130K/H(2mm pitch) |

|

Precision |

7μm/pixel |

|

Optional and specified |

Bottom camera |

|

IR Function |

Support (optional) |

Imaging

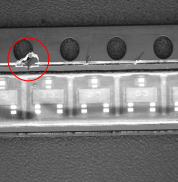

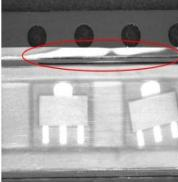

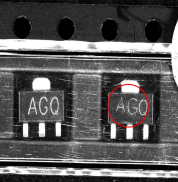

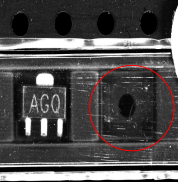

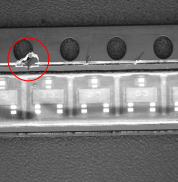

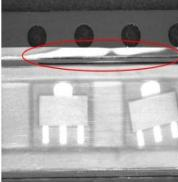

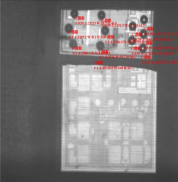

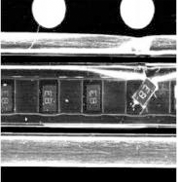

Tape seal damage |

Tape seal burrs |

Excessive interface size |

Missing plastic encapsulation |

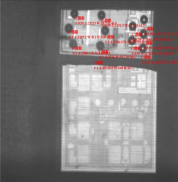

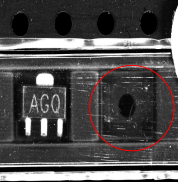

Chip damage (IR) |

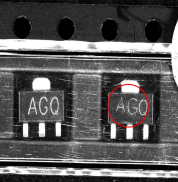

Chip misalignment |

Chip damage |

Unclear markings |

Missing chip |

Pin deformation |

- Product Description

-

- Commodity name: Fully automatic dual-lR tape feeding and ejection inspection machine

- Commodity ID: A-000

- 型号: Tiercel-RTR-ZD-13130

- 应用: <strong>Application:</strong> Applied to shipment inspection of finished products after taping, it can inspect supplier shipments to screen defects and ensure buyers receive qualified products.

• Customized Spectral Light Source<br> • High-speed Camera Inspection<br> • Supports Rapid Product Changeover

Capability

Project

Content

Product types

suitable for WLP, SOT, SOP, QFN, and other packaged ICs

Inspection Items

Tape sealing, character inspection, plastic-sealed body, pins, hidden cracks, etc

Tray and transmission method

Automatic loading and unloading

Lens and resolution

0.3X 2448*2048

Tape Width

Automatic track width adjustment,

ranging from 8-24mm (Customizable/Quick-changeable)

Reel Disk Size

7" / 13"

UPH

130K/H(2mm pitch)

Precision

7μm/pixel

Optional and specified

Bottom camera

IR Function

Support (optional)

Imaging

Tape seal damage

Tape seal burrs

Excessive interface size

Missing plastic encapsulation

Chip damage (IR)

Chip misalignment

Chip damage

Unclear markings

Missing chip

Pin deformation

Keywords :

AOI Equipment

Automation

Software Systems

AOI Vision Upgrade

Leave us a message