1. Monitor Installation: Size Optional.

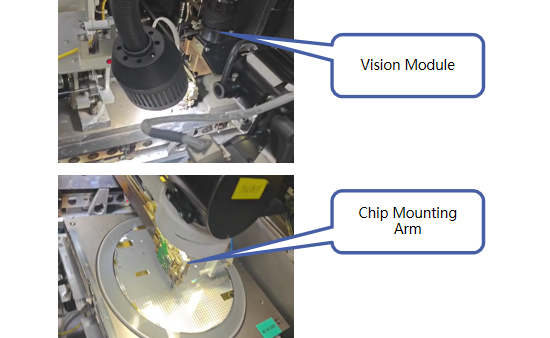

2. Die bonder vision module addition, after confirming the die bonding action through sensors, a photo is taken for image acquisition.

3. Automatic inspection process, imaging and image acquisition for inspection after die bonding.

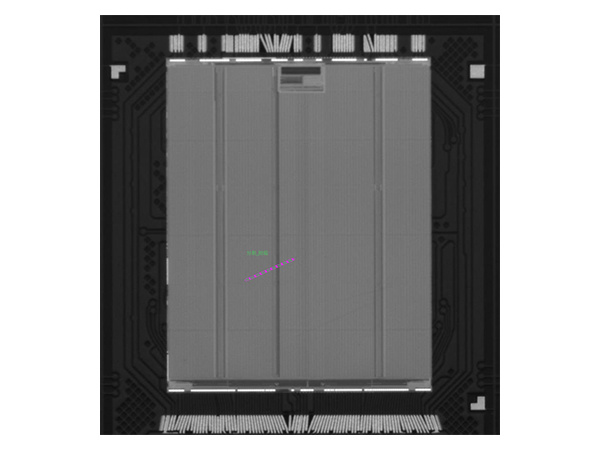

4. Inspection capabilities: chip presence, chip edge, chip angle, solder melt anomaly.

Equipment Scheme 1

Equipment Scheme 2

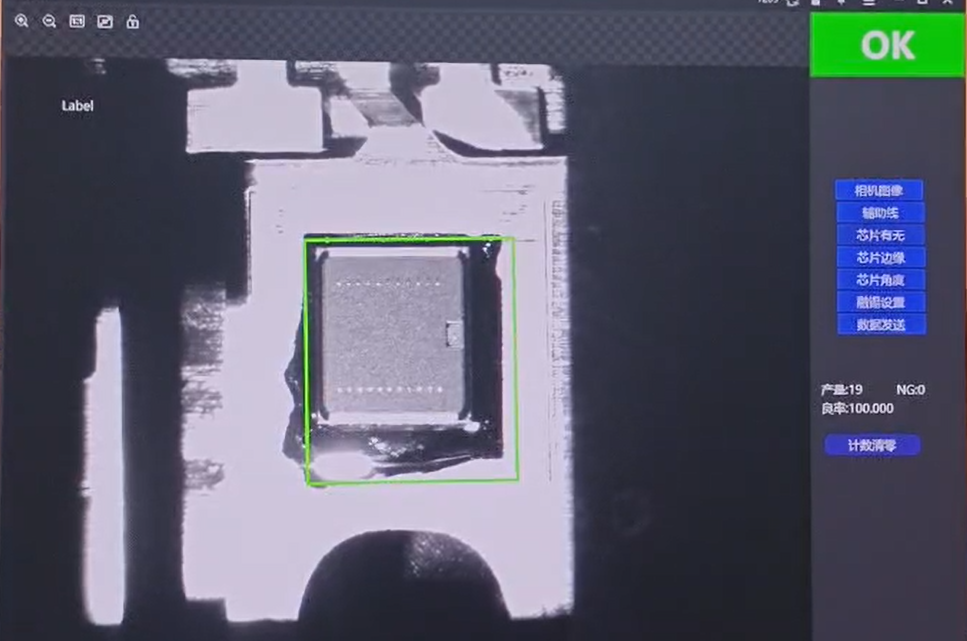

Software Introduction

‹ Left side of the software: real-time display of inspection results.

‹ Right side of the software: for debugging and production operations.

1. Adjustment of defect parameters is possible.

2. Optional real-time path for camera image acquisition and inspection.

3. Production data statistics.

Inspection Effect

- Product Description

-

- Commodity name: DB Eqiupment Retrofit

- Commodity ID: D-003

Equipment Scheme 1

Equipment Scheme 2

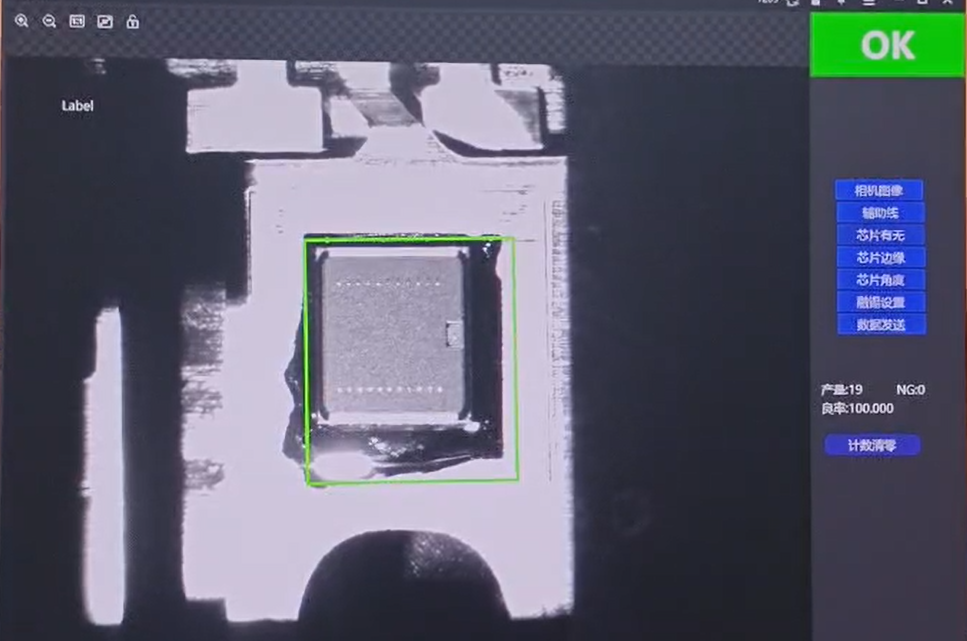

Software Introduction

‹ Left side of the software: real-time display of inspection results.

‹ Right side of the software: for debugging and production operations.1. Adjustment of defect parameters is possible.

2. Optional real-time path for camera image acquisition and inspection.

3. Production data statistics.

Inspection Effect

Keywords :

AOI Equipment

Automation

Software Systems

AOI Vision Upgrade

Leave us a message