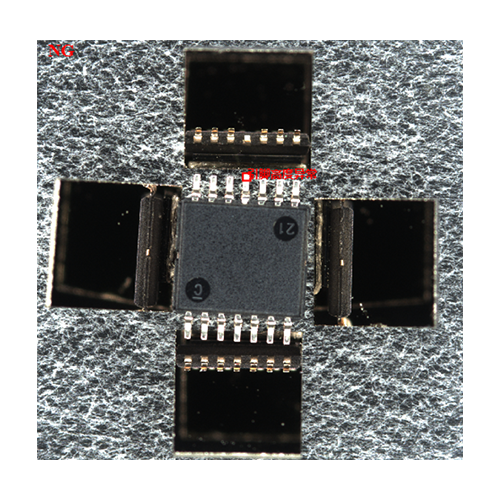

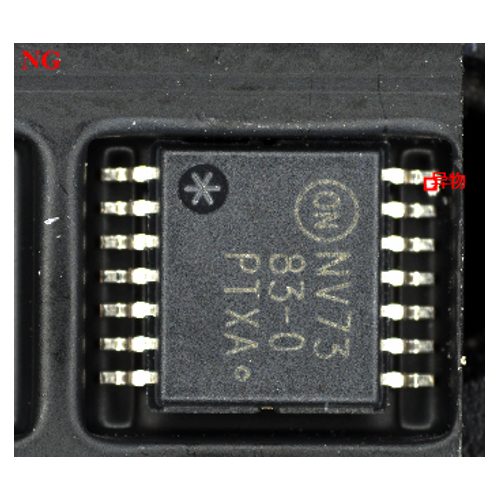

Pin Deformation

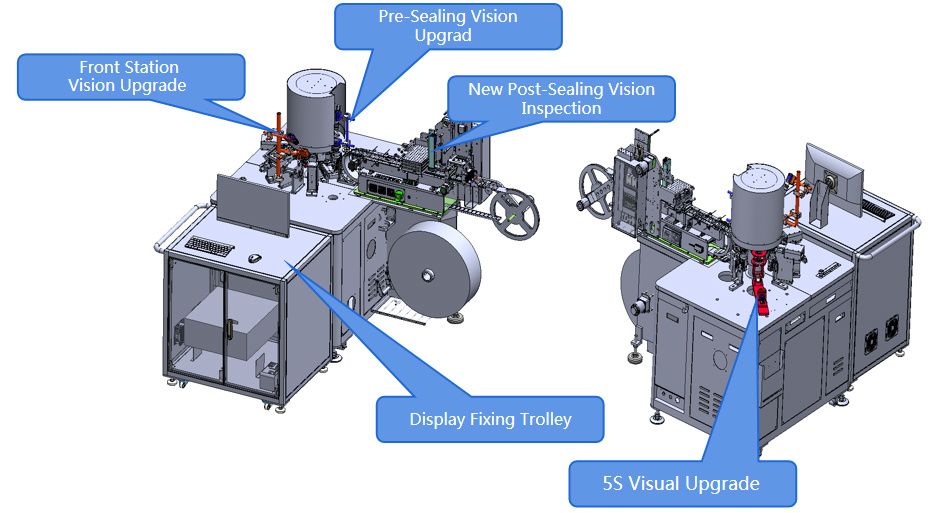

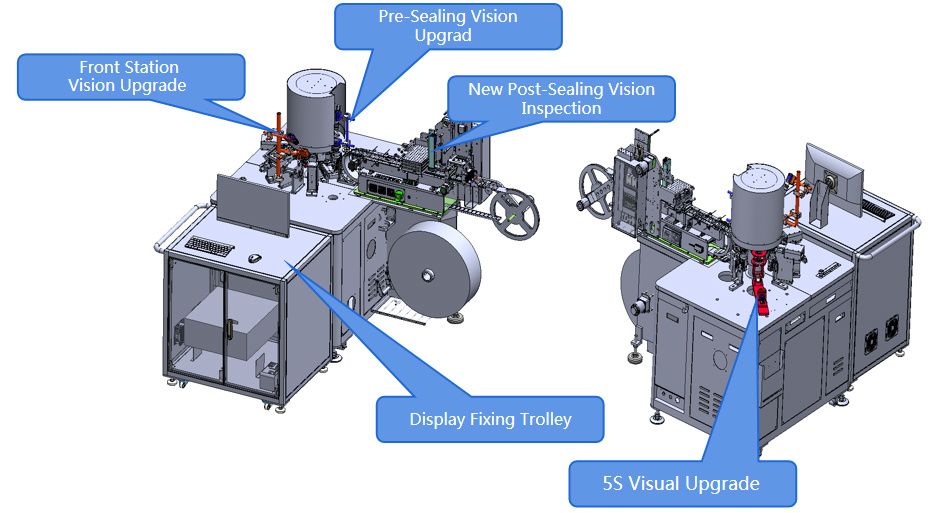

Renovation Schematic Image

Pre-Renovation Introduction

> The client's equipment is outdated, with optical vision hardware and inspection systems unable to meet the requirements for detecting process packaging defects. The over-inspection rate is as high as 2%-3%, and the missed inspection rate is up to 0.5%-1%. Additionally, there is no post-encapsulation inspection station, posing a risk of missed defects.

Post-Renovation Introduction

> Optimized and upgraded the inspection capabilities of three vision inspection stations (front side, 5S, and pre-encapsulation), and added a new encapsulation inspection station.

1. Upgraded the inspection capabilities of the original vision stations on the client's equipment and incorporated new vision modules, utilizing the JZ vision inspection system for defect detection. This significantly improved the over-inspection and missed-inspection rates, achieving an over-inspection rate of <0.05% and a missed-inspection rate of <0.01%, thereby enhancing the process yield of the equipment.

2. Made minor modifications to some hardware and wiring.

3. The original equipment's operational logic and UPH (Units Per Hour) were unaffected.

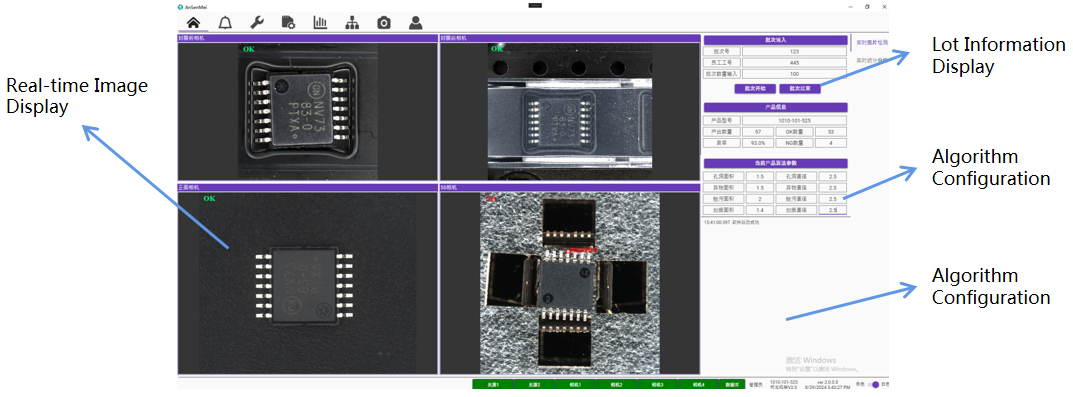

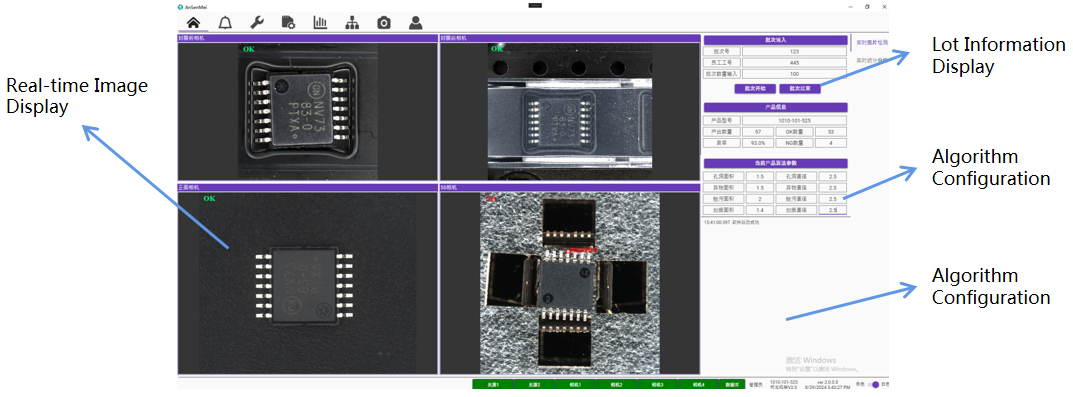

Software Introduction

1. Interface: Batch number, employee number, batch quantity; Current formula, output quantity, OK, NG, yield, etc.

2. Picture real-time display: product pictures and defects, equipment status.

3. Algorithm configuration: displaying algorithm parameter values.

Inspection Effect

- Product Description

-

- Commodity name: Handler Retrofit

- Commodity ID: D-001

Renovation Schematic Image

Pre-Renovation Introduction

> The client's equipment is outdated, with optical vision hardware and inspection systems unable to meet the requirements for detecting process packaging defects. The over-inspection rate is as high as 2%-3%, and the missed inspection rate is up to 0.5%-1%. Additionally, there is no post-encapsulation inspection station, posing a risk of missed defects.

Post-Renovation Introduction

> Optimized and upgraded the inspection capabilities of three vision inspection stations (front side, 5S, and pre-encapsulation), and added a new encapsulation inspection station.

1. Upgraded the inspection capabilities of the original vision stations on the client's equipment and incorporated new vision modules, utilizing the JZ vision inspection system for defect detection. This significantly improved the over-inspection and missed-inspection rates, achieving an over-inspection rate of <0.05% and a missed-inspection rate of <0.01%, thereby enhancing the process yield of the equipment.

2. Made minor modifications to some hardware and wiring.

3. The original equipment's operational logic and UPH (Units Per Hour) were unaffected.

Software Introduction

1. Interface: Batch number, employee number, batch quantity; Current formula, output quantity, OK, NG, yield, etc.

2. Picture real-time display: product pictures and defects, equipment status.

3. Algorithm configuration: displaying algorithm parameter values.

Inspection Effect

Keywords :

AOI Equipment

Automation

Software Systems

AOI Vision Upgrade

Leave us a message