Classification:

Hawkeye-IGT3150

IGBT Module Inspection

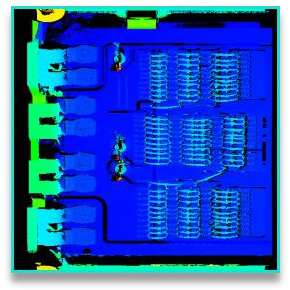

Application: DBC substrate online or offline inspection, IGBT module online and offline inspection.

• Utilize Multi-combination Lighting and Deep Learning Algorithms

• Compatible with Substrate and Module Inspection

• High Inspection Stability

• Fast Inspection Speed

Imaging

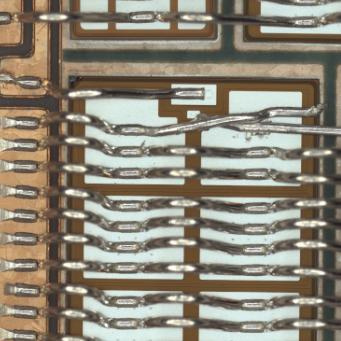

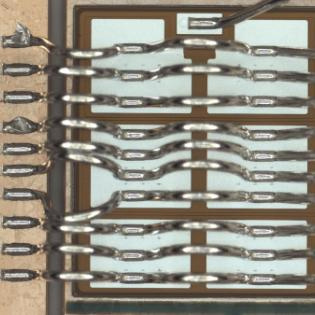

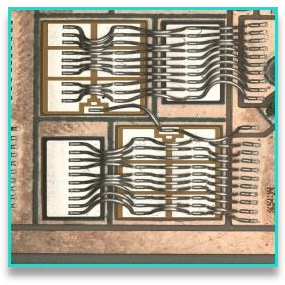

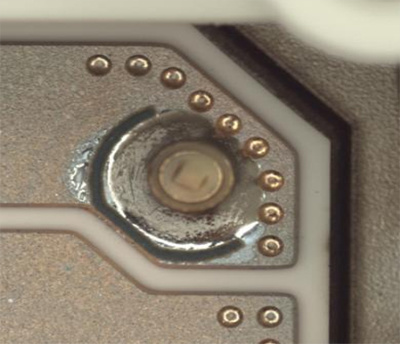

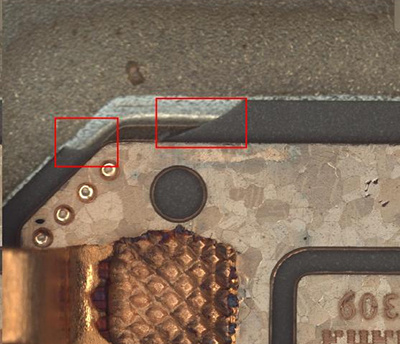

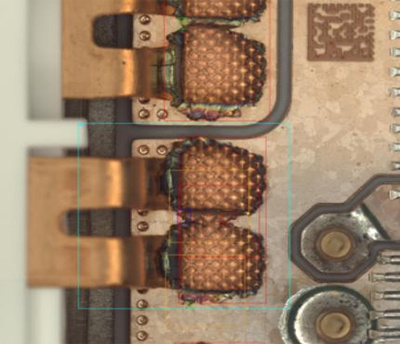

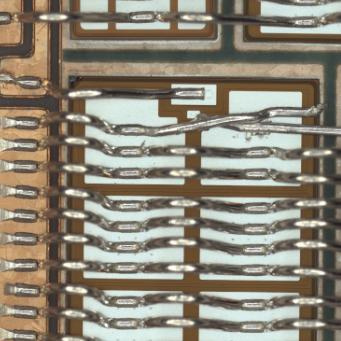

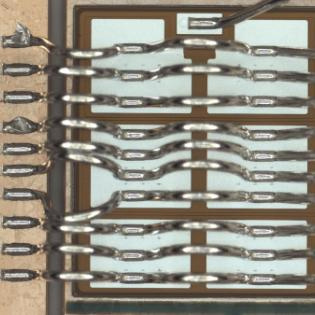

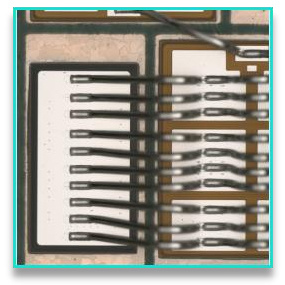

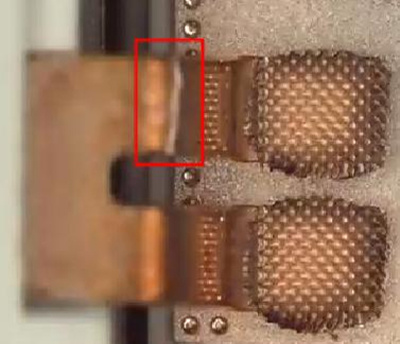

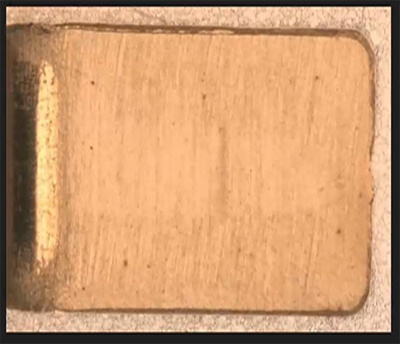

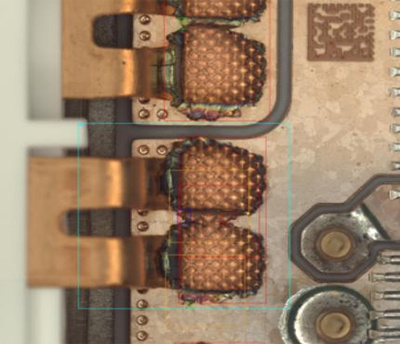

Wire Collapse |  Wire Clash |  Die Defect |  Pin Probe Position |

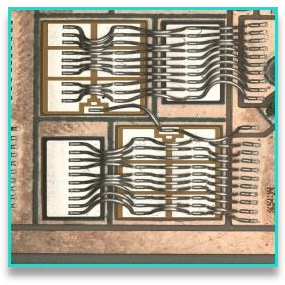

DBC Inspection |  DBC Defect |  3D Inspection |  Terminal Inspection |

Capability

| Project | Content |

| Product Type | DBC substrate/module |

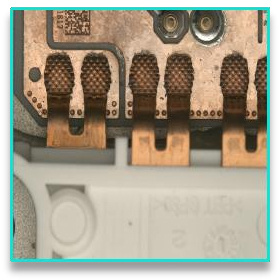

| Inspection Defect | Scratches Tin slag/foreign objects collapse lines/broken lines/wrong lines/damage/holes/cracks, etc |

| Track Width | 150-400mm |

| CT | 30s/pcs |

| Equipment Features | Adopting multi combination lighting and deep learning algorithms/ 1GBT compatible substrate and module inspection/high inspection stability/ fast inspection speed |

Imaging

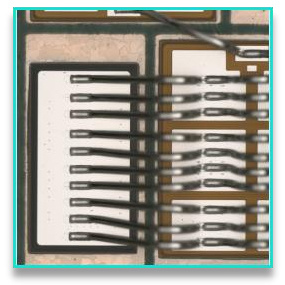

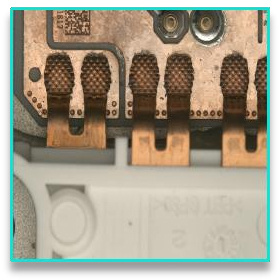

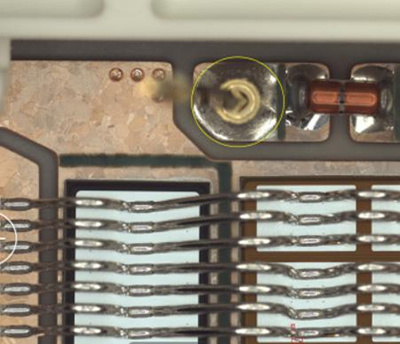

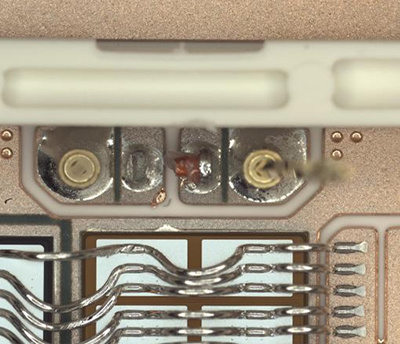

Concentricity Inspection |  Pin Needle Missing Welding |  Pin Needle with Insufficient Tin |  Terminal Fracture |  Unwelded Terminal |

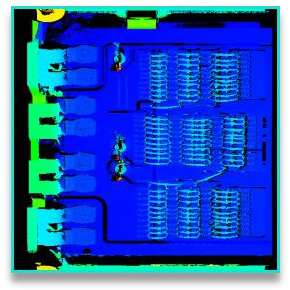

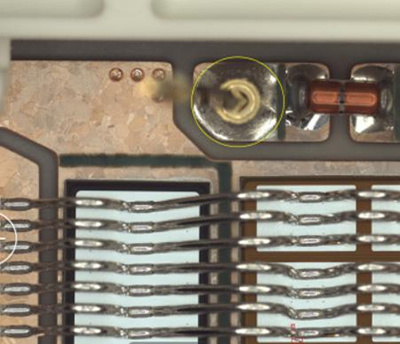

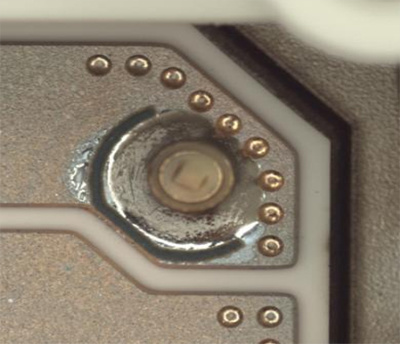

Foreign Objects on DBC |  DBC Defect |  Terminal Overflow beyond Groove |  Groove Crack |  NTC Malfunction |

- Product Description

-

- Commodity name: IGBT Module Inspection

- Commodity ID: A-006

- 型号: Hawkeye-IGT3150

- 应用: <strong>Application:</strong> DBC substrate online or offline inspection, IGBT module online and offline inspection.

• Utilize Multi-combination Lighting and Deep Learning Algorithms<br> • Compatible with Substrate and Module Inspection<br> • High Inspection Stability<br> • Fast Inspection Speed

Imaging

Wire Collapse

Wire Clash

Die Defect

Pin Probe Position

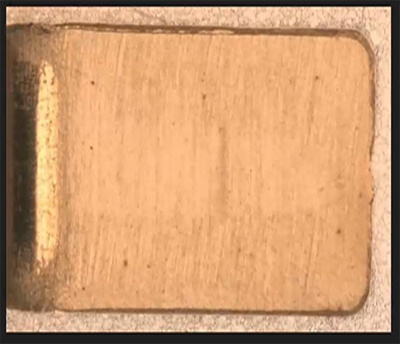

DBC Inspection

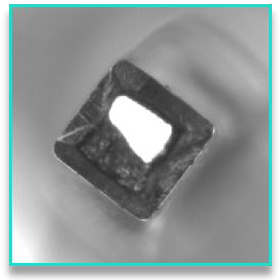

DBC Defect

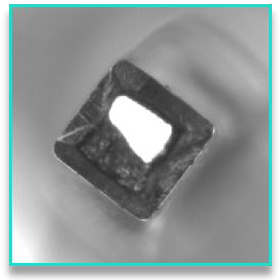

3D Inspection

Terminal InspectionCapability

Project Content Product Type DBC substrate/module Inspection Defect Scratches Tin slag/foreign objects collapse

lines/broken lines/wrong lines/damage/holes/cracks, etc

Track Width 150-400mm CT 30s/pcs Equipment Features Adopting multi combination lighting and deep learning algorithms/

1GBT compatible substrate and module inspection/high inspection stability/

fast inspection speed

Imaging

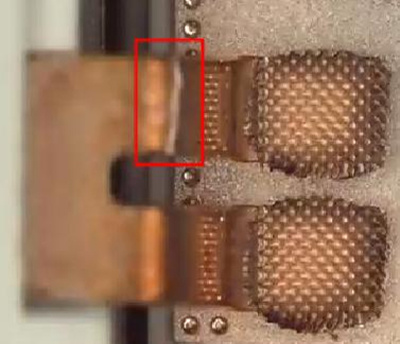

Concentricity Inspection

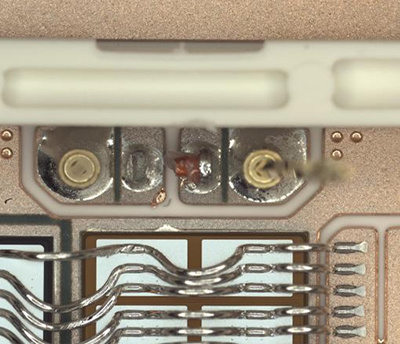

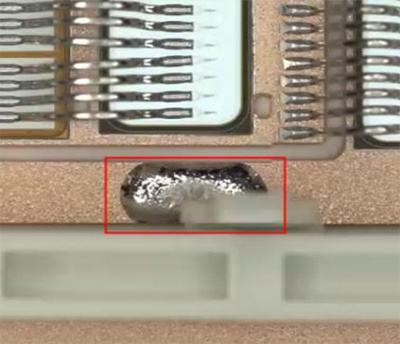

Pin Needle Missing Welding

Pin Needle with Insufficient Tin

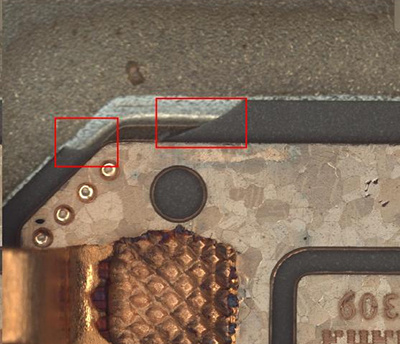

Terminal Fracture

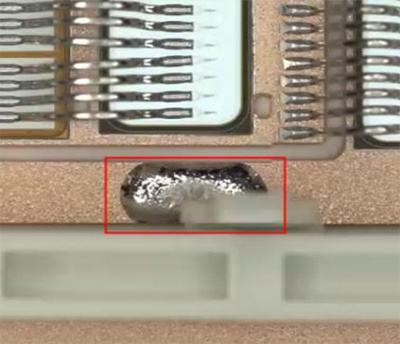

Unwelded Terminal

Foreign Objects on DBC

DBC Defect

Terminal Overflow beyond Groove

Groove Crack

NTC Malfunction

Keywords :

AOI Equipment

Automation

Software Systems

AOI Vision Upgrade

Leave us a message