Classification:

Hawkeye-TCP6010TR/TCP6010TT

Tray to Tray&Reel Chip Inspection Equipment

Application: Applied after final test, it can detect appearance defects in encapsulated devices by JZ 's patented 2D/3D vision inspection system.

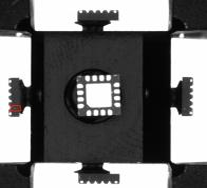

• Six-sided Appearance Inspection

• Optional 2D/3D Function Configuration

• Automatic Tape Collection

Capability

|

Project |

Content |

|

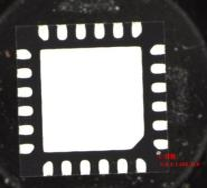

Product Type |

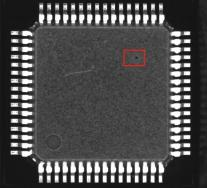

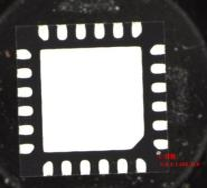

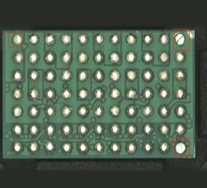

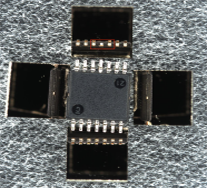

LGA、QFN、 BGA、QFP、SOP |

|

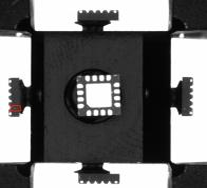

2D Inspection |

Cracks, adhesive residue, damage, abnormal solder balls, foreign objects, positional accuracy of solder balls |

|

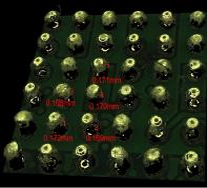

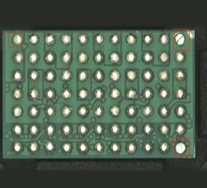

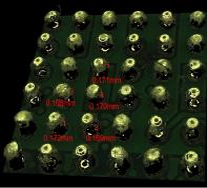

3D Inspection |

BGA height, coplanarity, etc |

|

Tray and transmission method |

JEDEC standard tray |

|

Product Size |

3mmx3mm-50mmx50mm(customizable beyond this range) |

|

Support Incoming Materials |

Tray to Tray&Tray to Reel&Reel to Tray |

|

2D Visual System |

25MP |

|

Pixel Resolution |

10μm/pixel |

|

Optional and customized |

5S/3D/Reel modules |

Imaging

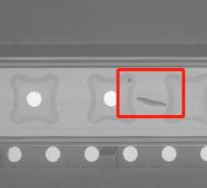

Surface voids in encapsulation |

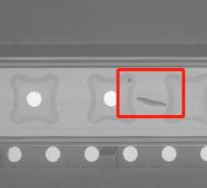

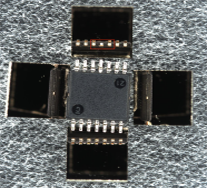

Pin deformation |

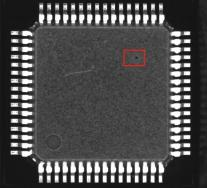

Foreign matter on the pad |

Solder ball damage & missing |

Side pin co-linearity |

5S inspection |

Cover film damage |

Pin stand-off height |

- Product Description

-

- Commodity name: Tray to Tray&Reel Chip Inspection Equipment

- Commodity ID: A-005

- 型号: Hawkeye-TCP6010TR/TCP6010TT

- 应用: <strong>Application:</strong> Applied after final test, it can detect appearance defects in encapsulated devices by JZ 's patented 2D/3D vision inspection system.

• Six-sided Appearance Inspection<br> • Optional 2D/3D Function Configuration<br> • Automatic Tape Collection

Capability

Project

Content

Product Type

LGA、QFN、 BGA、QFP、SOP

2D Inspection

Cracks, adhesive residue, damage, abnormal solder balls, foreign objects, positional accuracy of solder balls

3D Inspection

BGA height, coplanarity, etc

Tray and transmission method

JEDEC standard tray

Product Size

3mmx3mm-50mmx50mm(customizable beyond this range) Support

Incoming Materials

Tray to Tray&Tray to Reel&Reel to Tray 2D Visual System

25MP

Pixel Resolution

10μm/pixel

Optional and customized

5S/3D/Reel modules

Imaging

Surface voids in encapsulation

Pin deformation

Foreign matter on the pad

Solder ball damage & missing

Side pin co-linearity

5S inspection

Cover film damage

Pin stand-off height

Keywords :

AOI Equipment

Automation

Software Systems

AOI Vision Upgrade

Leave us a message