Classification:

Hawkeye-SMP4512

Strip Inspection Machine

Application: Applied in post-encapsulation or post-plating processes, it can detect the defects in the chip surface and pin, improving efficiency and yield.

• Multiple Feeding Methods are Optional

• Multi-combination Lighting and Deep Learning Algorithms

• False Action Alarm

• Support for Defect Marking and Mapping

Capability

|

Project |

Content |

|

Application Scenarios |

Both front and back sides of the strip and substrate are inspected |

|

Applicable Product Specifications |

Width: 40X100mm, length: 100x300mm |

|

Identifiable Defect Types |

Scratches, foreign objects, contamination, copper leakage, pressure damage, glue overflow, bubbles, damage, pits, discoloration, deformation, etc |

|

Imaging System |

Line scan camera, area array camera, laser profiler |

|

Cassette and Transmission Mode |

Right-in-right-out / Left-in-left-out |

|

Lens and Resolution |

2500W color area array / 5120 × 5120 |

|

Accuarcy |

5um/pixel |

|

Optional and Designated |

Inkjet marking or laser marking |

Imaging

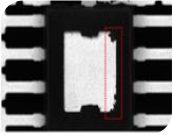

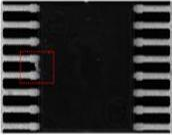

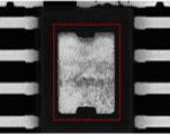

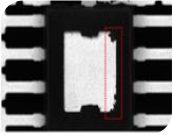

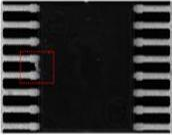

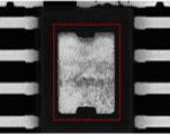

Solder Point |

Pit |

Color Deviation |

Contamination |

Damage |

Scratches |

Pollution |

Glue Overflow |

Solder Residue / Foreign Object |

Stains |

Watermarks |

Scratches |

- Product Description

-

- Commodity name: Strip Inspection Machine

- Commodity ID: A-004

- 型号: Hawkeye-SMP4512

- 应用: <strong>Application:</strong> Applied in post-encapsulation or post-plating processes, it can detect the defects in the chip surface and pin, improving efficiency and yield.

• Multiple Feeding Methods are Optional<br> • Multi-combination Lighting and Deep Learning Algorithms<br> • False Action Alarm<br> • Support for Defect Marking and Mapping

Capability

Project

Content

Application Scenarios

Both front and back sides of the strip and substrate are inspected

Applicable Product Specifications

Width: 40X100mm, length: 100x300mm

Identifiable Defect Types

Scratches, foreign objects, contamination, copper leakage, pressure

damage, glue overflow, bubbles, damage, pits, discoloration,

deformation, etc

Imaging System

Line scan camera, area array camera, laser profiler

Cassette and Transmission Mode

Right-in-right-out / Left-in-left-out

Lens and Resolution

2500W color area array / 5120 × 5120

Accuarcy

5um/pixel

Optional and Designated

Inkjet marking or laser marking

Imaging

Solder Point

Pit

Color Deviation

Contamination

Damage

Scratches

Pollution

Glue Overflow

Solder Residue / Foreign Object

Stains

Watermarks

Scratches

Keywords :

AOI Equipment

Automation

Software Systems

AOI Vision Upgrade

Leave us a message