Classification:

Tiercel-BGL-1520

Welding Line Inspection Equipment

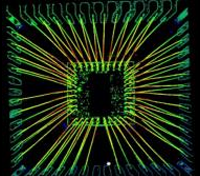

Application: Applied in chip and wire bonding stages, it effectively detects defects in chip appearance and bonding quality.

• Material Clip Binding Function

• 2D/3D Fusion Inspection

• Compatible with Products of Different Materials

Capability

|

Project |

Content |

|

Product Type |

Strip-shaped solder pad, frame and substrate-type solder wire products |

|

Inspection Items |

Chip reverse, chip error, chip silver glue/foreign matter, contamination, chip scratch, chip breakage, chip crack, less wire, ball off welding ball offset, broken wire, wire bending, wire tail length, etc |

|

Cutting Path Inspection Items |

Magazine-style cassettes with track conveyance |

|

Lens and Resolution |

1X lens, resolution: 9344×7000 |

|

UPH |

40-80strips/H (determined by the size of the material strip and the size of the die) |

|

Precision |

5μm/pixel |

|

Optional and Customized |

Mark pen; ink dotting, laser |

Imaging

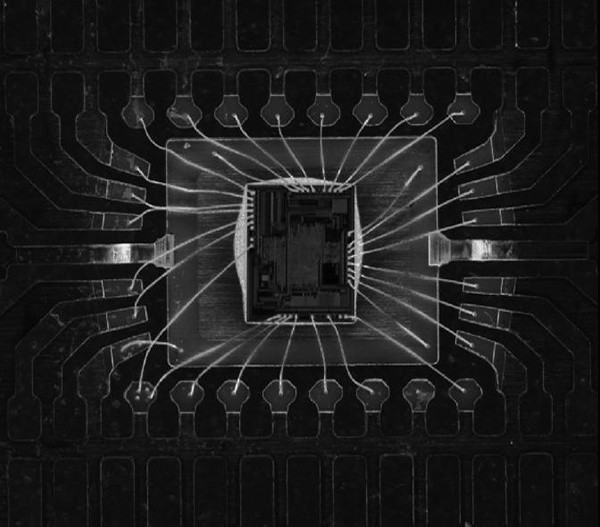

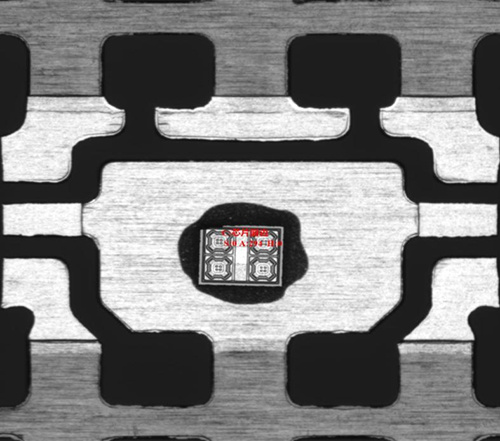

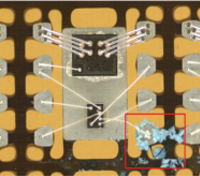

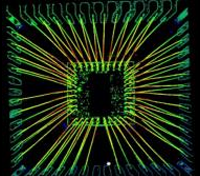

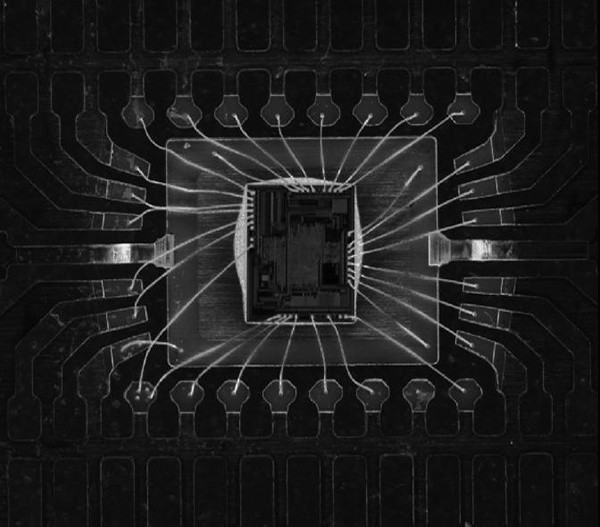

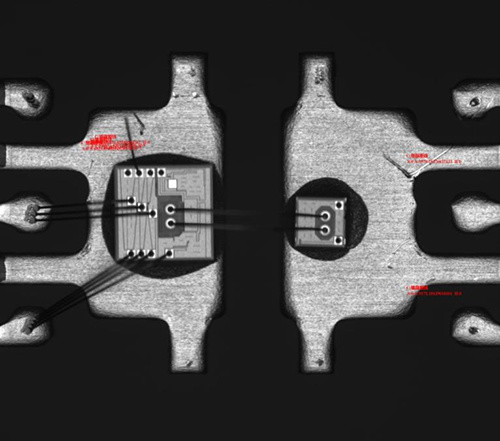

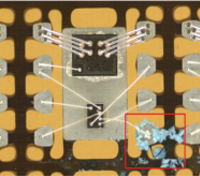

Short Circuit&Wire Breakage |

Abnormal Bonding Points |

Missing wire |

Wire Collapse |

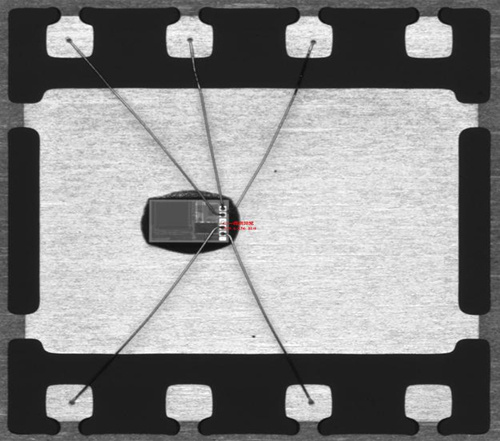

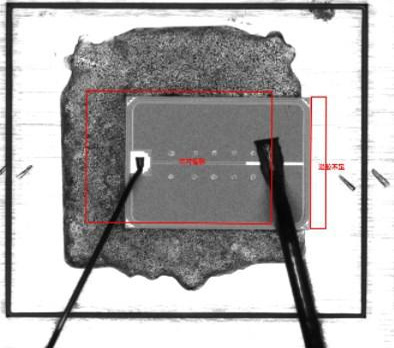

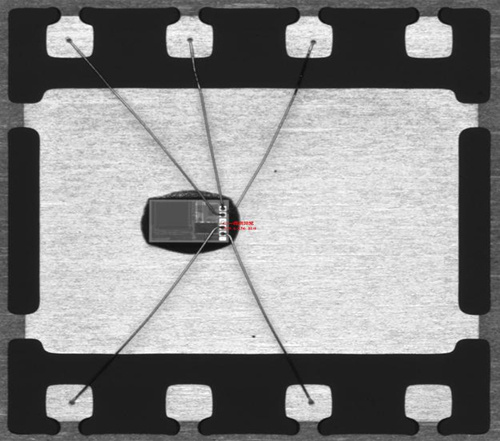

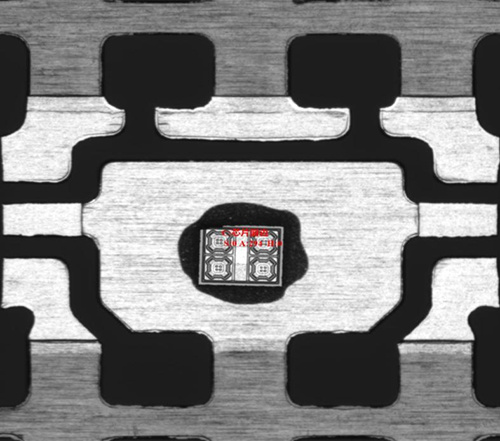

Hidden Cracks (IR) |

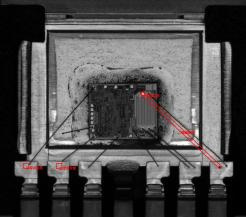

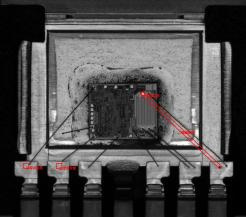

Die Chipping |

Die Contamination |

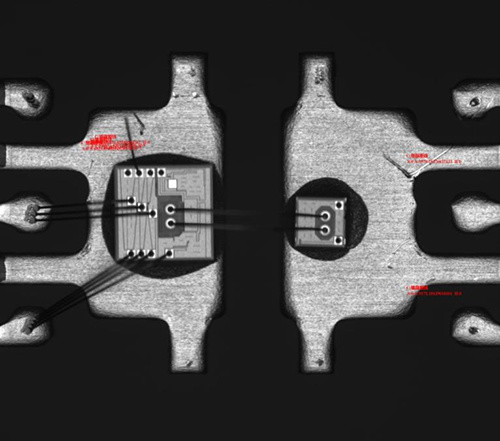

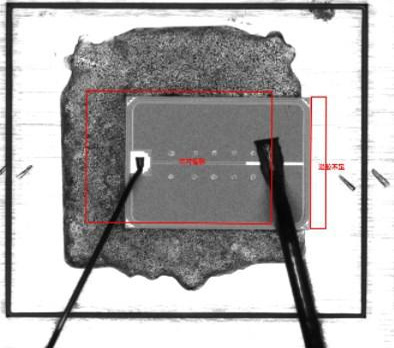

Chip Misalignment & Lack Solder |

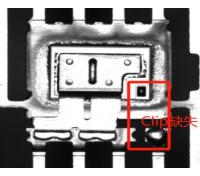

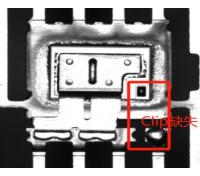

Clip Missing |

3D Inspection |

- Product Description

-

- Commodity name: Welding Line Inspection Equipment

- Commodity ID: A-003

- 型号: Tiercel-BGL-1520

- 应用: <strong>Application:</strong> Applied in chip and wire bonding stages, it effectively detects defects in chip appearance and bonding quality.

• Material Clip Binding Function<br> • 2D/3D Fusion Inspection<br> • Compatible with Products of Different Materials

Capability

Project

Content

Product Type

Strip-shaped solder pad, frame and substrate-type solder wire products

Inspection Items

Chip reverse, chip error, chip silver glue/foreign matter, contamination,

chip scratch, chip breakage, chip crack, less wire, ball off welding ball

offset, broken wire, wire bending, wire tail length, etc

Cutting Path

Inspection Items

Magazine-style cassettes with track conveyance

Lens and

Resolution

1X lens, resolution: 9344×7000

UPH

40-80strips/H

(determined by the size of the material strip and the size of the die)

Precision

5μm/pixel

Optional and Customized

Mark pen; ink dotting, laser

Imaging

Short Circuit&Wire Breakage

Abnormal Bonding Points

Missing wire

Wire Collapse

Hidden Cracks (IR)

Die Chipping

Die Contamination

Chip Misalignment &

Lack Solder

Clip Missing

3D Inspection

Keywords :

AOI Equipment

Automation

Software Systems

AOI Vision Upgrade

Leave us a message