Classification:

Hawkeye-WST6055

Wafer 2D Defect Inspection System

Application: Applied to shipment after wafer cutting/postseal cutting, it inspects um-level defects on 6-12 inch wafers, provides yield feedback and outputs map to optimize efficiency.

• Compatible Frame Wafer

• IR Hidden Crack Support

• INK inkjet Support

Capability

|

Project |

Content |

|

Product Type |

6 ", 8 ", 12 " frame wafer |

|

2D Inspection ltems |

Foreign objects, residual glue, particles, scratches, hidden cracks, contamination, CP deviation, excessive area, etc Cutting channel deviation and chipping |

|

Cutting Path Inspection Items |

6 ", 8 ", 12 " frame cassetee |

|

Lens and Resolution |

2x( 2.75um)/3. 5x( 1. 57um)/ 5x( 1. 1um)/7. 5x( 0.73um)/ 10x( 0. 55um) |

|

Precision |

0. 55μm/pixel |

|

Optional and Customized |

INK module, IR module |

|

Inspectable Area |

Front side inspection(standard configuration), back side inspection(customizable) |

Imaging

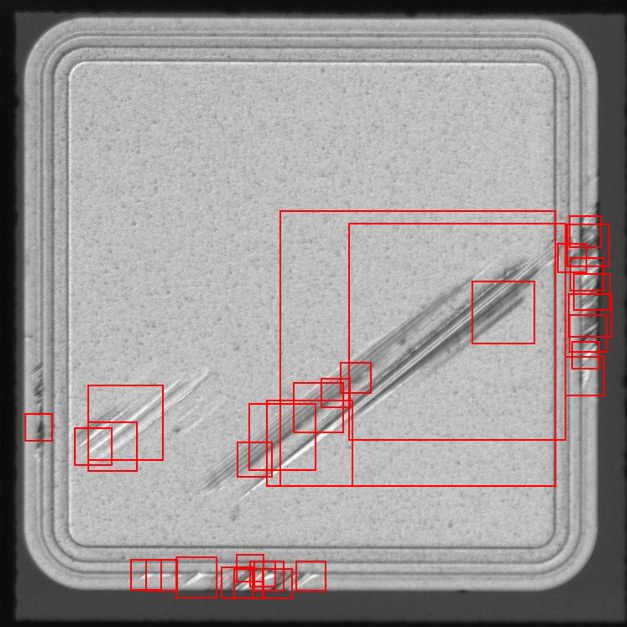

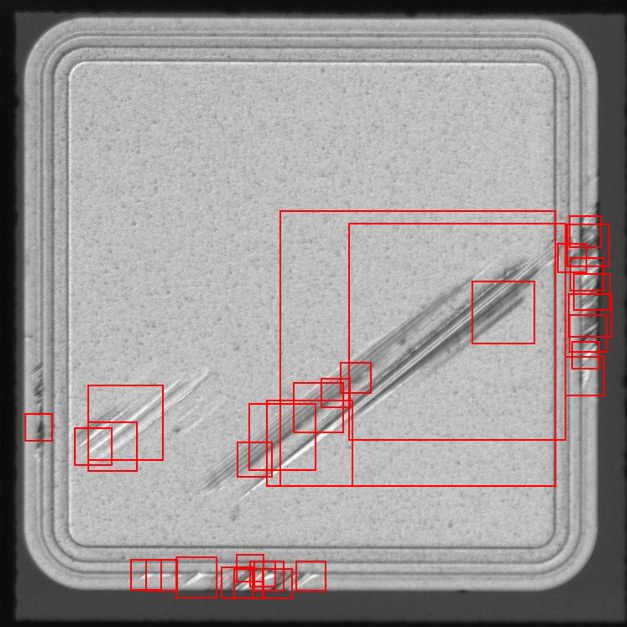

Scratch |

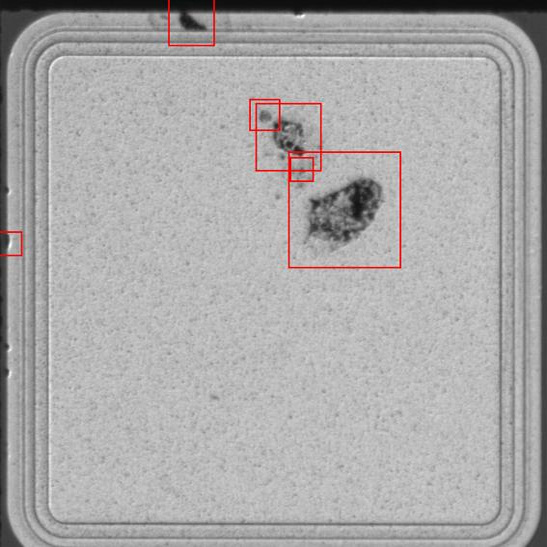

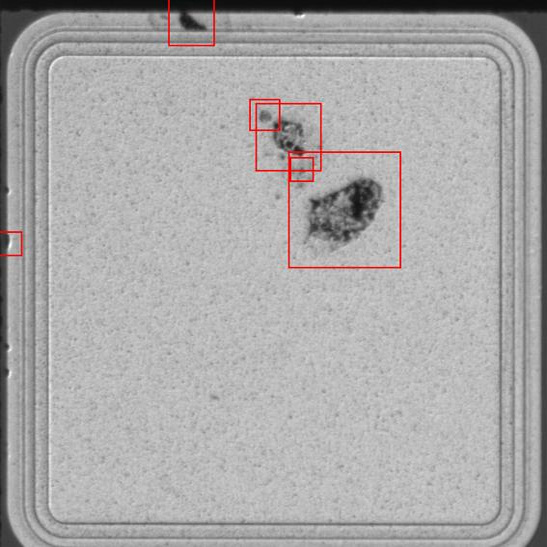

Dirt |

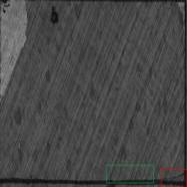

IR with Crack |

IR without Crack |

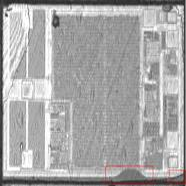

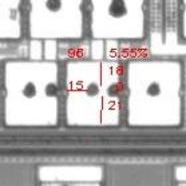

Probe (Pad corrosion) |

Probe (skewing) |

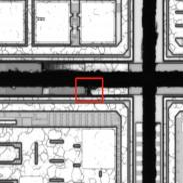

Cutting edge chipping |

Ink dot inspection |

- Product Description

-

- Commodity name: Wafer 2D Defect Inspection System

- Commodity ID: A-002

- 型号: Hawkeye-WST6055

- 应用: <strong>Application:</strong> Applied to shipment after wafer cutting/postseal cutting, it inspects um-level defects on 6-12 inch wafers, provides yield feedback and outputs map to optimize efficiency.

• Compatible Frame Wafer<br> • IR Hidden Crack Support<br> • INK inkjet Support

Capability

Project

Content

Product Type

6 ", 8 ", 12 " frame wafer

2D Inspection ltems

Foreign objects, residual glue, particles, scratches, hidden cracks, contamination, CP

deviation, excessive area, etc

Cutting channel deviation and chipping

Cutting Path

Inspection Items

6 ", 8 ", 12 " frame cassetee

Lens and

Resolution

2x( 2.75um)/3. 5x( 1. 57um)/

5x( 1. 1um)/7. 5x( 0.73um)/ 10x( 0. 55um)

Precision

0. 55μm/pixel

Optional and Customized

INK module, IR module

Inspectable Area

Front side inspection(standard configuration), back side inspection(customizable) Imaging

Scratch

Dirt

IR with Crack

IR without Crack

Probe (Pad corrosion)

Probe (skewing)

Cutting edge chipping

Ink dot inspection

Keywords :

AOI Equipment

Automation

Software Systems

AOI Vision Upgrade

Leave us a message